Specialty processing systems as diverse as your process

From confections to sterile aseptic packaging, Wright Process Systems has both the experience and knowledge base to manage your specialty processing needs. For more than 20 years, we have designed and built processing systems for a wide variety of specialty applications, custom-creating facilities for our customers’ specific needs, and to meet the best practices within their niche markets. Through our collaborative working model, The Wright Advantage, we advance our company mission of continuous process improvement to help you achieve maximum efficiency.

Powder

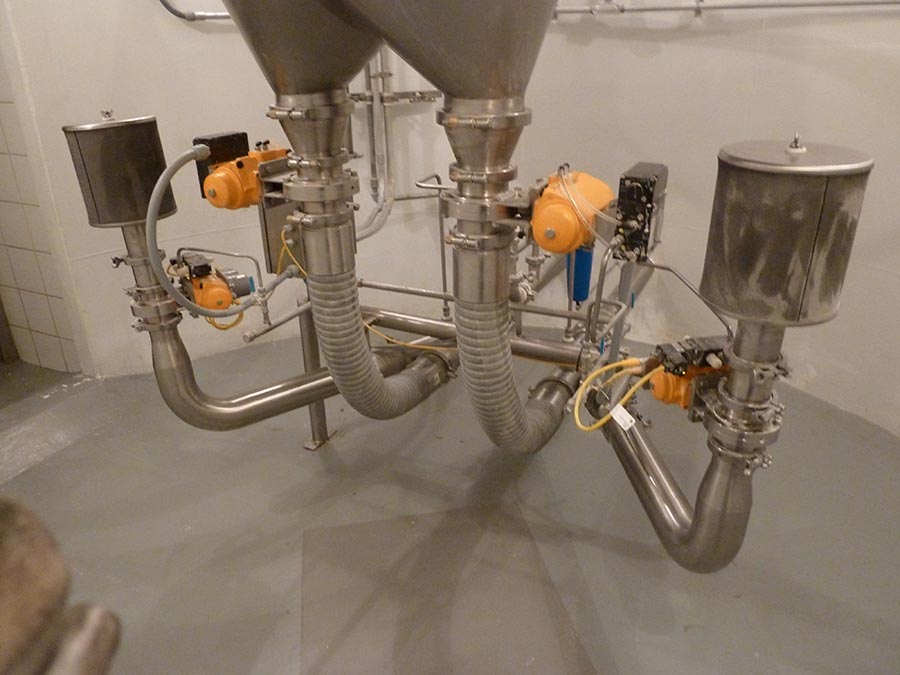

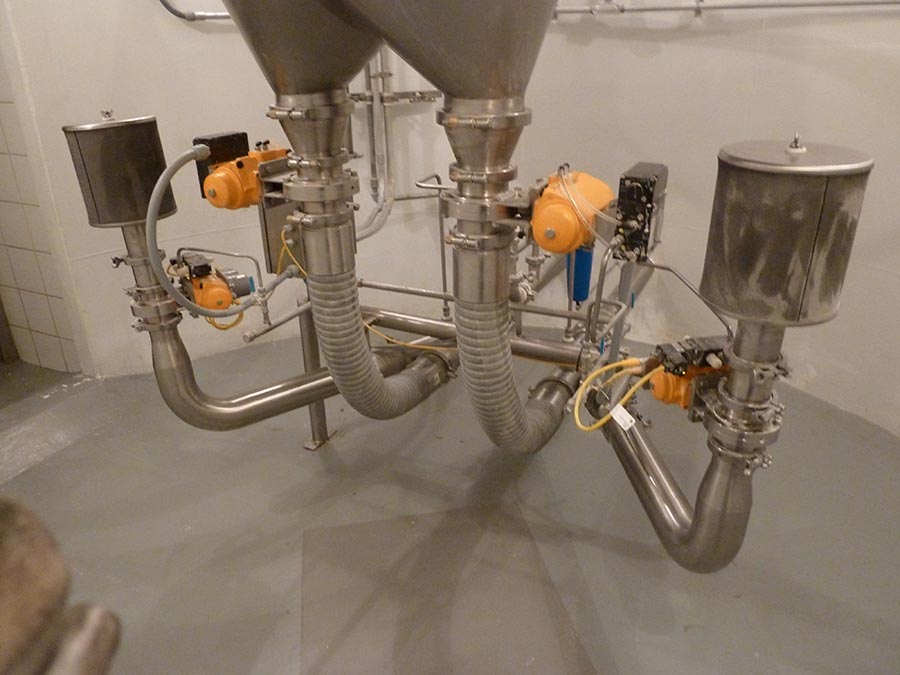

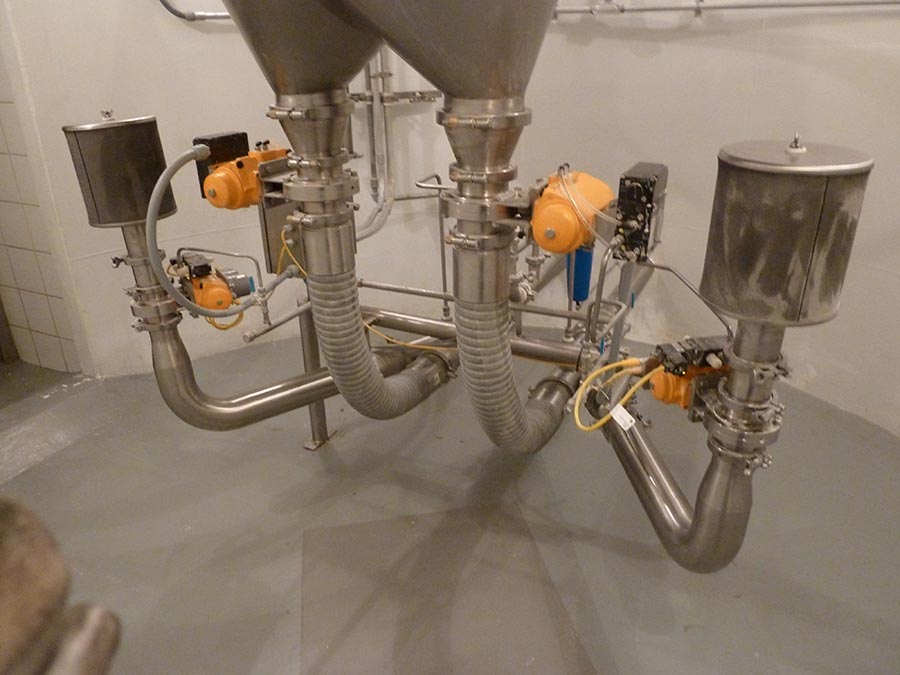

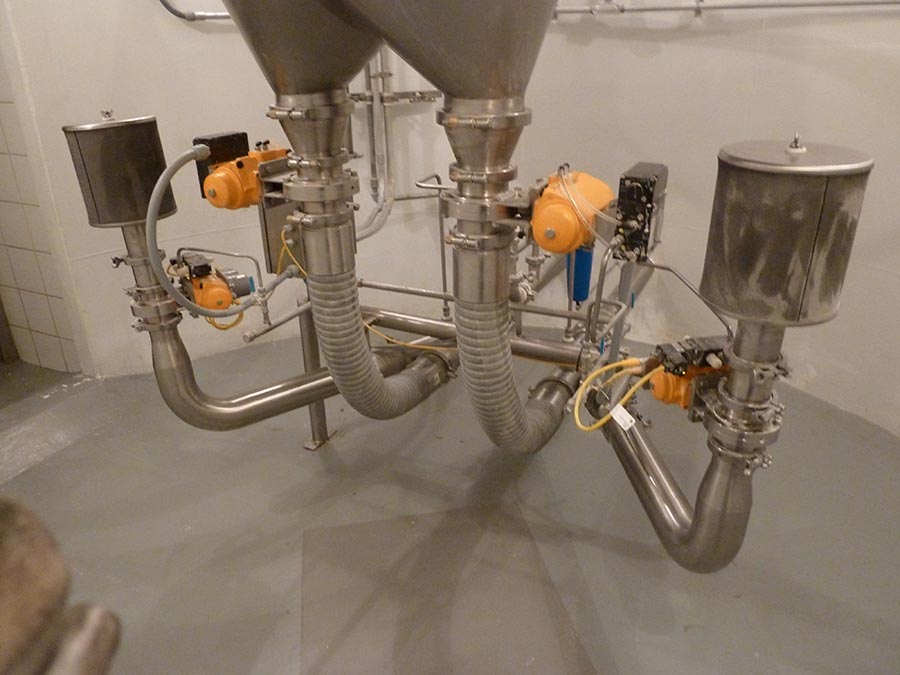

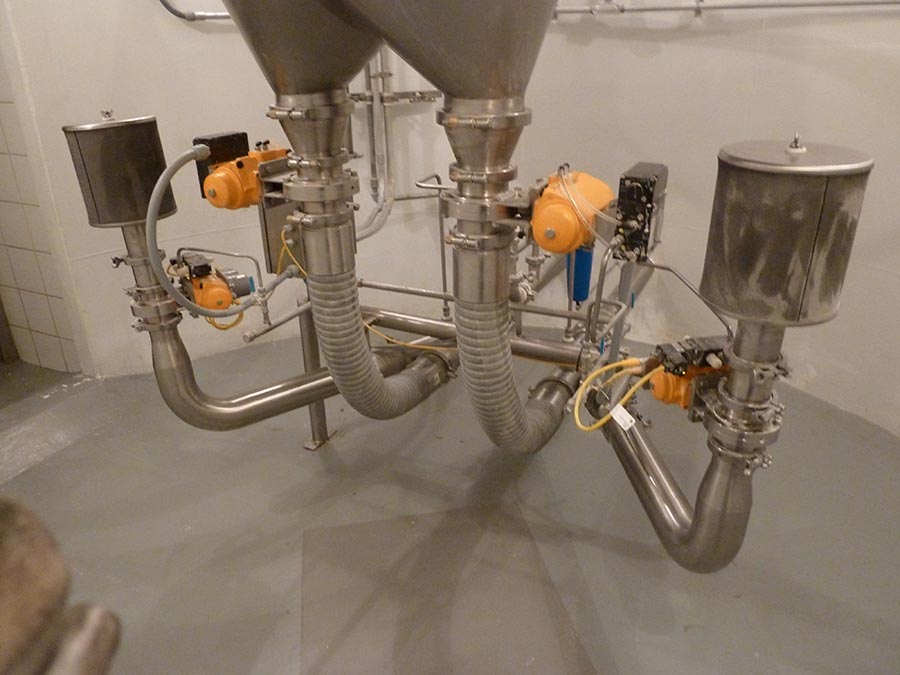

Bringing experience, industry insight, and collaboration to powder processing

Wright Process Systems brings significant experience to the installation and service of powder processing and powder production systems. By partnering with specific, purpose-driven channel partners, we can offer the latest, most effective powder processing and production equipment, which our in-house technicians are qualified to install, maintain, and repair. Working with our network of manufacturing partners, we bring a team-oriented approach that can provide you with everything you need for your operation, from parts to service to a complete system design-and-build.

Within the powder processing and production field, we install and service a variety of systems, including:

- Mix and blend systems

- Sifting and clarifying systems to remove solids or undesirable particles

- Powder size reduction systems

- Powder repacking systems

- Powder drying systems

- Bulk bag, tote, drum, and bag loading and unloading systems

- Powder hydration and liquification systems

- Powder reconstitution systems

- Powder handling and conveyance systems

- Air, screw conveyor, and vacuum handling systems

- Dehumidifier installations

- Rotary magnet installations

- Mechanical conveyance systems

- Screen and rotary filter equipment

- Storage silos and vessels

- Metering and distribution systems

Filtration

Adaptable processing for optimized production

Our engineers not only bring substantial experience in a variety of filtration systems; they also understand how to adapt, optimize, and apply different filtration processes for a wide selection of products. Whether you are microfiltering milk for extended shelf life or de-salting whey with diafiltration during cheese processing, we can design and build the system you need.

Systems we have designed and installed for filtration processing include:

- Microfiltration

- Ultrafiltration

- Nanofiltration

- Reverse osmosis

- Product concentrators

- Water purification and treatment

- De-ionized water systems

- Boiler feedwater filtration and other utility usages

- Filtration byproduct handling, including cow water, polished water, and waste streams

Confection

Turning your sweet dreams into reality

From chocolate to hard candy to chewing gum, confectionary processing is one of the most demanding, highly specific areas of food processing. For decades, Wright Process Systems has worked closely with the makers of sweet treats of all shapes, colors, and sizes—from ice cream to candy bars and everything in between. We understand the regulations and the technical requirements of confectionary production. We bring deep experience to the design and construction of confectionary process systems. Most important, we know how to take your sweet-tooth visions from concept to reality.

Wright Process Systems confectionary system work has included:

- Stainless jacketed piping fabrication

- Fully “pig-able” designs

- Freezing and vacuum extrusion

- Gentle product handling considerations

- Customized product recovery systems

- Metal detection and product safety

- Tempering, de-tempering, and crystalizing mitigation

- Ingredient addition, including dairy cream injection

- Traditional and modern conching

- Product-specific automation and controls

- Inclusion and ingredient additions

- Powder and semi-solid conveyance systems

- Heat tracing and temperature controls

- Jacketed vessels and containers

- Recirculation loops to prevent product set-up

- Product-specific cleaning and sanitation systems

- Utility distribution systems, including hot water, steam, cooling water, plant water, and compressed air

- On-demand hot water recirculation systems

Bakery

Bringing superior quality, variety, and efficiency to baked goods processing

Wright Process Systems has worked with industrial bakeries and large-scale baked goods producers for more than two decades. Our process engineers can build a system that maintains the highest quality, meets all applicable regulations, and maintains high levels of efficiency, from the input of ingredients to the final packaging of the finished product. Also, our forward-thinking approach to process design can yield an adaptable system, helping you vary production for a greater mix of products.

Systems we have designed, built, and installed for the baked goods industry include:

- Dough mixer installations, including liquid ingredient distributions piping

- Batter batching system modifications and optimizations

- Fryer line installations

- High-pressure pumping circuits for yeast and batter products

- Clean-in-place systems for high-soils bakery equipment

- Dough mixer line with egg distribution piping

- Bakery walk-in oven installation, including gas piping and exhaust flue ducting

- Topping depositor installation

- Oven installation, including make-up and exhaust air system

- Wash and sanitation systems

- Fire-rated construction improvements to high-temperature baking areas

- Fire-suppression and sprinkler systems

- CO2 and non-liquid fire protection systems for oil and fryer lines

Aseptic

Direct and indirect aseptic process systems to add life to your food and beverage products

Wright Processing Systems designs, installs, and services both direct and indirect aseptic systems. All systems produce packaged products that meet the requirements of the FDA and USDA, or the Grade A Pasteurized Milk Ordinance for dairy products. Our design and engineering teams can create customized systems that produce new and unique packaging that helps ensure longer shelf life while being easier on the environment. The end result is a product that has more varied uses, allowing you greater market penetration and better return on your processing system investment.

Systems we have designed and installed for the aseptic processing and packaging industry include:

- Sterile jacketed silos and tanks

- Sterile air push piping circuits (non-pumped)

- Nitrogen / inert gas blankets

- Beverage, milk, soy, and sport drink aseptic systems

- Aseptic fillers – bottles, cans, Tetra Pak foils, pails, and drums

- Indirect, non-contact heating systems

- Scraped surface heat exchanger systems

- Culinary / sterile steam and air system