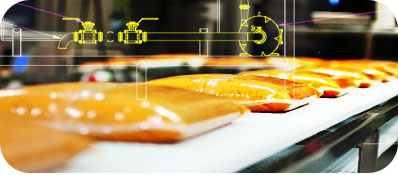

Basics of food safety for food and beverage processors

Among the many food safety practices and products recommended by Wright Process Systems, here are a few of the basic practices that we suggest as a baseline for our customers in the food and beverage processing industry.

- Using particulate strainers on products to pull out any foreign objects from the food or beverage.

- Employing magnets to pull out the bulk of magnetic (ferrous) metal pieces from the product, and then using metal detectors downstream in the process to reject products that still contain ferrous particulates missed by the magnets. These measures can be used in both liquid and powder streams.

- Using color and imaging analysis tools to evict foreign objects. For example, red spectrum analysis works well for bulk red apples, evicting foreign objects and anything that is spoiled or not ripe.

- Heating certain products to a level that ensures that all unwanted organics and bacteria have been killed.

- Installing cleaning and sanitation systems, such as wash down systems, CIP systems, and chemical distribution systems, to assure the highest level of cleanliness in production environments.

- For perishables, cooling the products to preserve quality and extend shelf life.

- Also for perishables, using inert gases, such as nitrogen instead of air, to provide a barrier between the product and airborne contamination ingression.

- Implementing documentation standards and systems for compliance with regulatory bodies, customer requirements, third party reviewers, and others.

- Integrating fast-response systems for recalls and risk abatement, and to protect public safety in the event of a foodborne illness.

- Building systems from high-quality materials to promote product quality, including stainless steels, food-grade plastics, non-corrosive resins, and others. These materials are preferred over low-quality steel that can flake or rust, painted materials, wood, or other materials with lower structural quality.

- Using UV lights to sterilize liquid streams of bacteria.

- Installing instrumentation to monitor and control process variables to assure conditions are within set parameters.

- Constructing hygiene junctions where personnel don and doff protective clothing, hair nets, show covers, and other hygienic coverings to minimize the risk of outside contamination, and also to contain product soils within a production area.

- Conditioning and filtering building air into a process room with HEPA filters and positive indoor air pressure.